Plaster Workshop

- Jack Hainsworth

- Nov 13, 2018

- 1 min read

In today's induction, we were shown the plaster workshop, used for sculpting and creating and and using molds. For the practice section, we were each given some clay, and were told to create a design which would later by cast in plaster.

We rolled out the clay into the shape of a postcard, around half an inch thick, and created our designs with it. We then used strips of clay to create the walls of the mold, and sealed them so that the plaster would not leak when we poured it in.

We then made our plaster of Paris, by sprinkling plaster into a tub of water into small peaks formed, and then mixed it together with our fingers so that there were no lumps. The plaster was then poured into our mold, first by coating the edges and then pouring the rest on top. This ensures that the plastic gets all of the detail, and that there are no air bubbles on the surface.

(This is an example of a similar process, which we were also shown during the induction)

After lunch, we all came back and took our casts out of the molds. Mine unfortunately broke as I tried to get it out, most likely because it hadn't fully set. I think this is because there was too much water in my mixture.

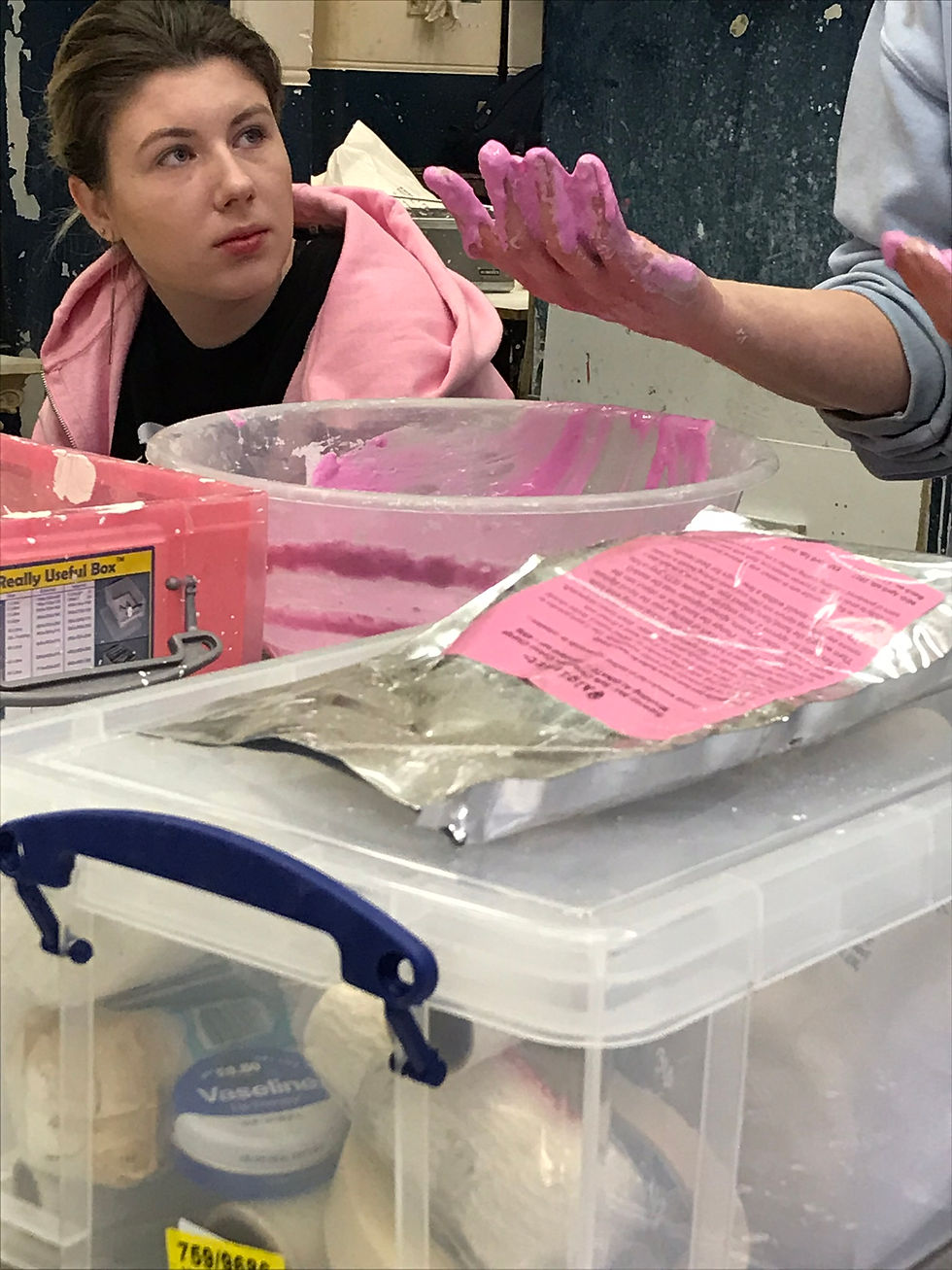

After our practical session, another student demonstrated casting his arm, in a slightly different, flexible material.

It starts off bright pink, and slowly turns white as it cures (sets). It was then poured around the student's arm, inside a drinks bottle, and left to cure.

Comments